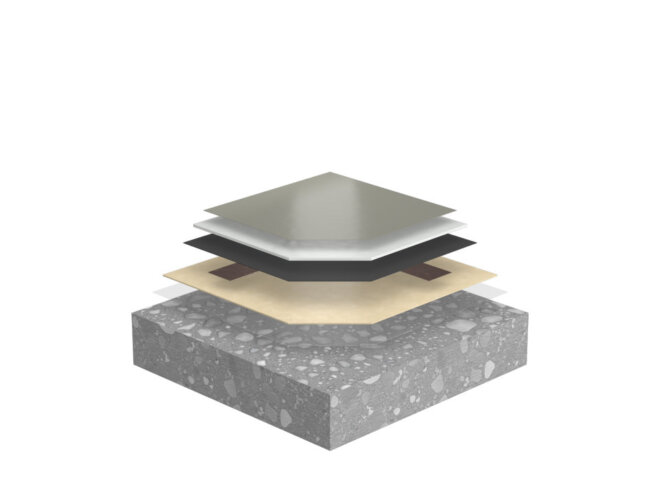

EP coating system, aqueous, electrically conductive, low-emission

- Sto Iraq

- Sto Worldwide

for ESD protection zones, for server rooms, for clean rooms, for battery rooms, for potentially explosive atmospheres, for production halls and storage areas for electronic components, for production halls in the automotive industry

normal flammability (EN 13501-1)

RAL colour fan K 5, StoColor System, NCS, others, limited colour matching options

Sto sustainability data sheet, low-emission according to AgBB test criteria

System resistance < 35 megohms in combination with StoPox WL 113 or StoPur WV 210, fulfils personal protection requirements even at a nominal voltage > 500 V in combination with StoPox WL 118, very good light resistance, system structure available for clean rooms: StoFloor Cleanroom WB 110

Concrete (moisture load on the back), cement screed (moisture load on the back), calcium sulphate screed, magnesia screed

Product complies with EN 1504-2, Product complies with EN 13813