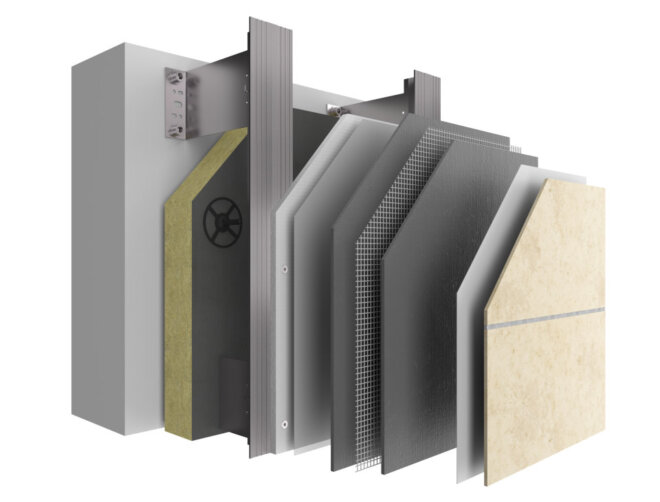

Seamless, ventilated façade with natural stone tiles

- Sto Iraq

- Sto Worldwide

Old and new buildings, suitable for passive house standard thanks to certified substructure, large system structures (e.g. > 60 cm) possible

Substructure consisting of wall bracket and support profile (StoVentro Y): easily adjustable substructure made of a combination of stainless steel and aluminium with the lowest thermal bridge coefficients, in timber construction with timber base battens

Class B1 according to DIN 4102-1, flame-retardant, in defined system structure class A2-s1, d0 according to EN 13501-1 when using StoVentec support panel A or according to national standard when using StoVentec support panel, fire barriers according to national specifications may be required

Extensive colour selection thanks to various natural stones, e.g. Sto-Fossil Bavaria Yellow, Sto-Fossil SKL, Sto-Granit Bianco Ozieri, Sto-Granit Final Red, Sto-Gneis Dark Green, Sto-Gabbro Nero Transvaal, Sto-Gabbro Super Dark

StoStone natural stone tiles, surface polished, honed, sandblasted, brushed, edges bevelled as standard (also without bevel on request), can be combined with plastic façade elements made of Verolith granulate

0.045 W/(m*K) and better0.042 W/(m*K) and better0.040 W/(m*K) and better0.035 W/(m*K) and better0.032 W/(m*K) and better

Stone

Sound insulation improvement up to 14 dB (A)

Curtain-type, rear-ventilated façade

For the decorative design of individual, high-quality natural stone surfaces, building physics benefits thanks to rear ventilation of the façade (moisture, sound and summer heat insulation), compensation of unevenness thanks to variable substructure, lowest thermal bridge coefficients thanks to own substructure made of a stainless steel/aluminium combination, passive house-certified, thermal bridge-free substructure possible, highly weather-resistant, very high crack resistance

Masonry such as bricks, sand-lime bricks, aerated concrete, exposed and facing brickwork, concrete, panelled construction (three-layer panels), timber construction

Extensive detailed solutions, quick installation

Fleece-laminated mineral wool, large insulation thicknesses possible, system design also possible without insulation

The respective national approvals apply.