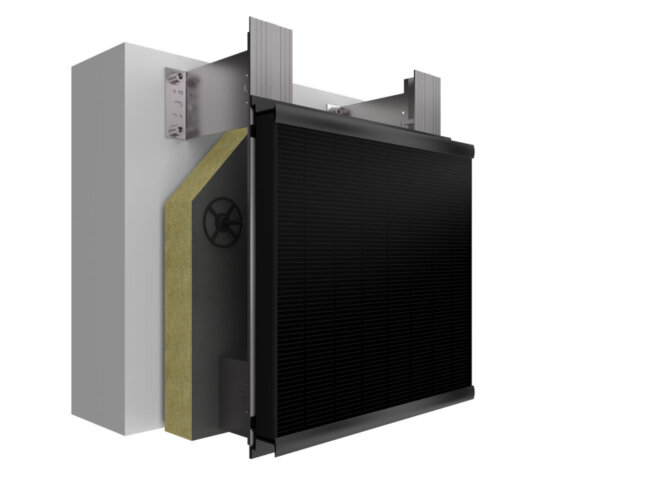

Joint-emphasised, curtain-type, rear-ventilated façade with framed photovoltaic modules

- Sto Iraq

- Sto Worldwide

Old and new buildings, application limit in accordance with national building regulations, suitable for passive house standard thanks to certified substructure, large system structures (e.g. > 60 cm) possible

via insertion rail attached to the substructure on site, easily adjustable substructure made of a stainless steel/aluminium combination, in timber construction with timber base battens

Fire behaviour (class) according to EN 13501-1: B-s1, d0, flame-retardant, according to national standard in the defined system structure, fire barriers according to national specifications may be required

anthracite colours

High-quality, homogeneous appearance, combination of different formats possible, combination with other surfaces as mixed façade possible

Performance guarantee: min. 97 % in the first year, then maximum reduction of 0.7 % per year up to 25 years, modules from Austrian production

Easy to dismantle into unmixed individual components thanks to modular system design, return of defective or disused photovoltaic modules by the manufacturer

Remove dirt with clean water and a soft sponge or cloth, care and cleaning instructions available separately

Sound insulation improvement of up to 10 dB (A)

High mechanical load capacity

Curtain-type, rear-ventilated façadeUtilisation of renewable energy

Photovoltaics integrated into the façade to generate electrical energy, module technology: photovoltaic modules on a monocrystalline basis, installed output: > approx. 180 Wp/m², efficiency: ≥ 18 %, advantages in terms of building physics thanks to rear ventilation of the façade (moisture, sound and summer heat insulation), compensation of unevenness thanks to variable substructure, lowest thermal bridge coefficients thanks to own substructure made of a stainless steel/aluminium combination, passive house-certified, thermal bridge-free substructure possible, highly weather-resistant

Masonry such as brick, sand-lime brick, aerated concrete, exposed and facing brickwork, concrete, panelled construction (three-layer panels), timber construction

Hanging the factory-made panels into the substructure on site, quick and weather-independent installation, extensive detailed solutions, connection cabling: decentralised box concept (3 pieces) with MC4 connectors

Fleece-laminated mineral wool, large insulation thicknesses possible, system design also possible without insulation