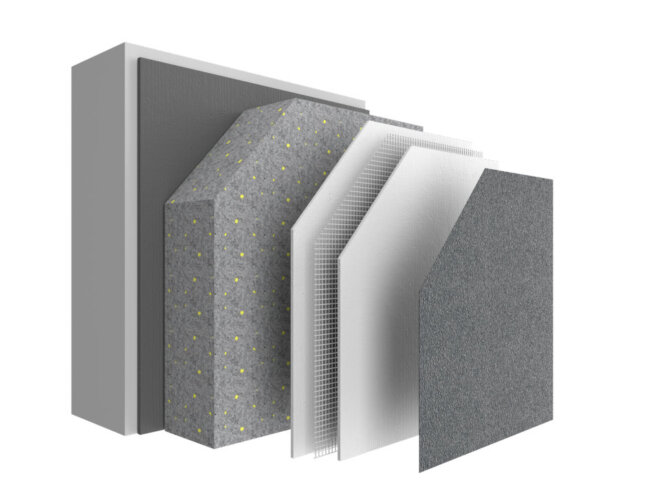

Robust external thermal insulation composite system with maximum crack and impact resistance

- Sto Iraq

- Sto Worldwide

Old and new buildings, suitable for buildings according to the lowest energy standard

Glueing, for substrate unevenness ≤ 1 cm/m (in solid construction), glueing and dowelling, for substrate unevenness ≤ 2 cm/m (in solid construction), mechanical fixing with Sto-Rotofix plus

normal flammability

Can be tinted according to StoColor system, lightness value < 15 possible

Organic and silicone resin plasters as well as plaster with Lotus-Effect® Technology in scratch and grooved plaster structure or as modelling plaster, plastic façade elements made of Verolith granulate, flat facing bricks and prefabricated plaster elements

0.032 W/(m*K) and better0.035 W/(m*K) and better0.040 W/(m*K) and better0.042 W/(m*K) and better0.045 W/(m*K) and better

Facade plasterConcreteMetallicWood look

High mechanical load-bearing capacity, up to 15 joules in the standard structure, with high-impact-resistant structure load-bearing capacity up to 60 joules, in the corresponding system structure - Highest hail resistance class 5, ball impact-resistant according to DIN 18032-3, hail, heavy rain and hurricane-resistant according to FIBAG simultaneous test

normal and betterhigh mechanical load capacity

External thermal insulation composite system

Maximum impact and shock resistance of 15 joules (single-layer) and 60 joules (double-layer), system safety - more than 100 million square metres of reference area, crack-resistant due to organic coating structure, high resistance to microorganisms (algae and fungi), intensive, dark colours (light reference values

Masonry such as bricks, sand-lime bricks, aerated concrete, exposed and facing brickwork, concrete, panelled construction (three-layer panels), timber construction (solid, frame and panel construction), steel construction (stud and frame construction), existing external thermal insulation composite systems (doubling)

Cement-free, ready-to-use system components, no intermediate coating required, special protection against algae and fungi thanks to a double coat of paint, can be applied by machine, projects can also be realised in the cooler months of the year thanks to the use of QS Technology

Lotus-Effect® Technology optional

Thermal insulation board made of EPS up to 400 mm

The respective national approvals apply.