CEM repair system, plastic-modified, dry spraying process, statically co-active

- Sto Iraq

- Sto Worldwide

As a concrete substitute in the dry spraying process, for reinforcing concrete structures, to increase the concrete cover, also under CFRP lamellae, to increase fire resistance, as a repair mortar for the repair principle of cathodic corrosion protection, to restore the passivity of reinforcing steel

Class A2-s1, d0 in accordance with EN 13501-1, REI 90 in accordance with EN 13501-2, hydrocarbon curve F90 in accordance with EN 4102-1, EBA temperature curve (corresponds to fire scenario RABT with extended full burning time), non-combustible (in accordance with MVVTB)

Available in silos in Germany, suitable for use in hydraulic structures

Large layer thickness in one work step, application even under dynamic load, flexible work interruption and long conveying distances, high fire resistance, permanently electrically conductive (KKS), corrosion protection available in the system, fine filler available in the system

concrete

Dry spraying method

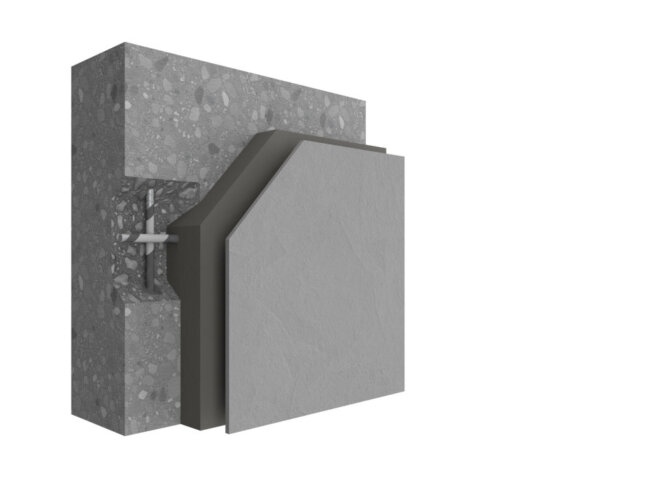

Dry spray mortar, class R4 repair mortar in accordance with EN 1504-3

EN 1504-3, principles 3, 4, 7, methods 3.3, 4.4, 7.1 and 7.2